FIBERGLASS SINGLE EXPANSION JOINT SOCKET X SPIGOT, NO O-RING (ID)

The Fiberglass Single Expansion Joint Socket x Spigot (No O-Ring) is a precision-engineered solution designed for above-ground fiberglass conduit systems. This joint is essential for managing the challenges of thermal expansion and contraction, helping maintain the structural integrity and longevity of fiberglass conduit installations. By allowing the conduit to naturally expand and contract in response to temperature fluctuations, it prevents stress, misalignment, and potential damage to the system. Its durable construction ensures long-term reliability, making it a vital component in environments with varying temperatures.

Applications:

- Above-Ground Fiberglass Conduit Systems: Ideal for industrial and utility installations that require movement accommodation and impact resistance.

- Utility and Infrastructure Projects: Used by utility companies to protect fiberglass infrastructure in areas exposed to temperature fluctuations.

- Critical Installations: Ensures stability in long fiberglass conduit spans that experience expansion and contraction due to environmental changes.

Key Features:

- Fiberglass Socket x Spigot Design: Provides a secure, straightforward connection for easy integration with existing fiberglass conduit systems.

- Guided Installation: Features a yellow line indicator on the nipple end to ensure proper placement and secure installation.

- Flexible Placement: Suitable for mid-span placement in fiberglass ducts between 50 ft and 200 ft, with recommended intervals of 200 ft for longer spans.

- Optimal Location: Designed for positioning close to the quarter point of the conduit span to maximize joint performance.

Benefits:

- Reduces Stress: Absorbs expansion and contraction, preventing damage to the fiberglass conduit system.

- Ease of Use: The yellow line indicator simplifies alignment, ensuring proper installation with minimal effort.

- Durable Construction: Built for above-ground fiberglass conduit systems, providing reliable performance even in harsh environmental conditions.

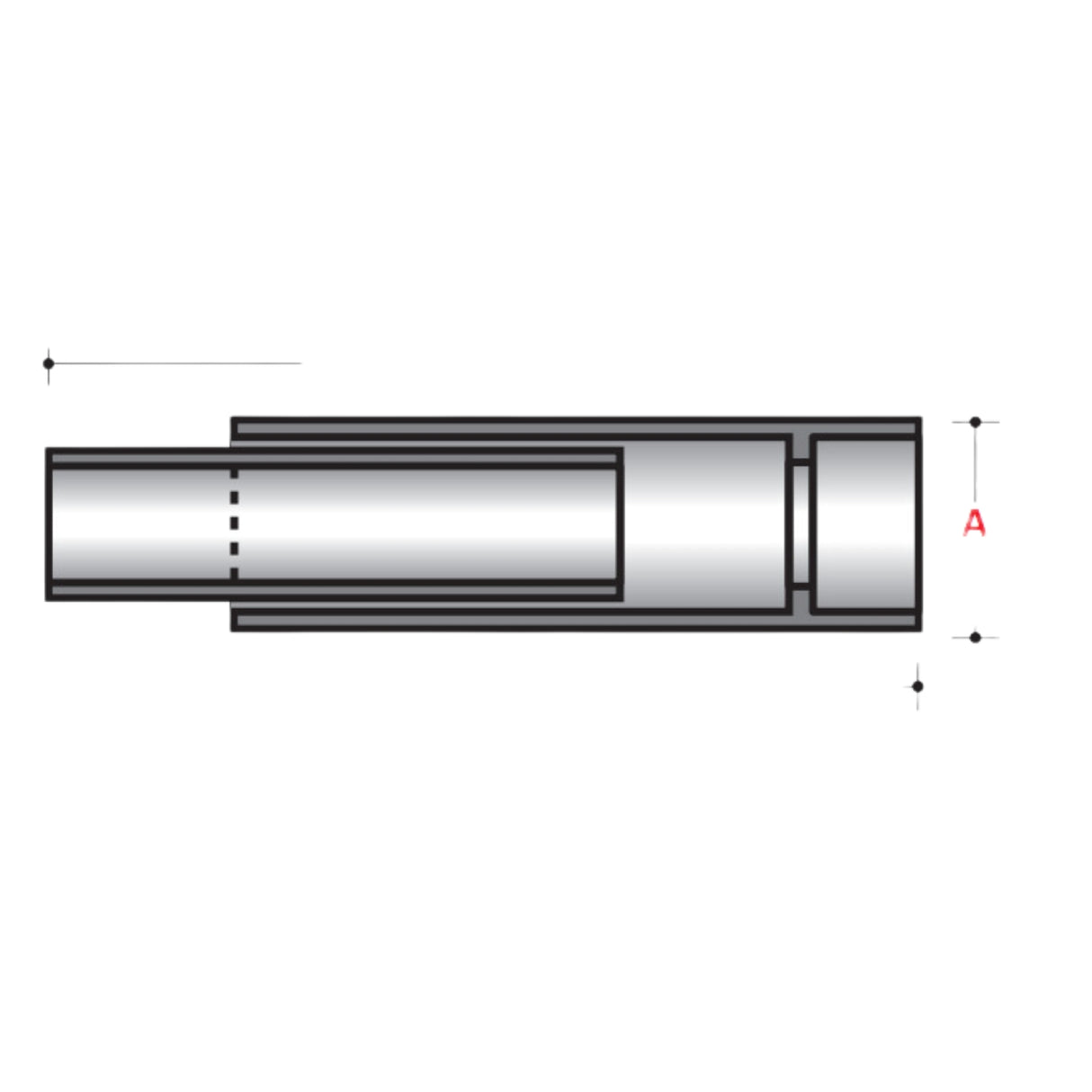

| NOMINAL SIZE | TYPE | ITEM NO (ABOVE GROUND) | A | B | L - MIN | L - MAX | WEIGHT (LBS) | WEIGHT (KG) |

|---|---|---|---|---|---|---|---|---|

| 2" | SW | 20D-SW-34 | 2.305" (59) | 12" (305) | 15" (381) | 21" (533) | 0.78 | 0.35 |

| 2-1⁄2" | SW | 25D-SW-34 | 2.805" (71) | 12" (305) | 15" (381) | 21" (533) | 0.97 | 0.44 |

| 3" | SW | 30D-SW-34 | 3.305" (84) | 12" (305) | 15" (381) | 21" (533) | 1.10 | 0.50 |

| 3-1⁄2" | SW | 35D-SW-34 | 3.805" (97) | 12" (305) | 15" (381) | 21" (533) | 1.38 | 0.63 |

| 4" | SW | 40D-SW-34 | 4.305" (109) | 12" (305) | 15" (381) | 21" (533) | 1.59 | 0.72 |

| 4" | HW | 40D-HW-34 | 4.409" (112) | 12" (305) | 15" (381) | 21" (533) | 2.12 | 0.96 |

| 4-1⁄2" | SW | 45D-SW-34 | 4.805" (122) | 12" (305) | 15" (381) | 21" (533) | 1.73 | 0.79 |

| 4-1⁄2" | HW | 45D-HW-34 | 4.909" (125) | 12" (305) | 15" (381) | 21" (533) | 2.39 | 1.09 |

| 5" | SW | 50D-SW-34 | 5.305" (135) | 12" (305) | 15" (381) | 21" (533) | 1.96 | 0.89 |

| 5" | MW | 50D-MW-34 | 5.409" (137) | 12" (305) | 15" (381) | 21" (533) | 2.60 | 1.18 |

| 5" | HW | 50D-HW-34 | 5.465" (139) | 12" (305) | 15" (381) | 21" (533) | 3.04 | 1.38 |

| 6" | SW | 60D-SW-34 | 6.305" (160) | 12" (305) | 15" (381) | 21" (533) | 2.35 | 1.07 |

| 6" | MW | 60D-MW-34 | 6.409" (163) | 12" (305) | 15" (381) | 21" (533) | 3.11 | 1.41 |

| 6" | HW | 60D-HW-34 | 6.465" (164) | 12" (305) | 15" (381) | 21" (533) | 3.63 | 1.65 |