REDUCING ADAPTER - ABOVE GROUND

When it comes to above-ground conduit repairs, Champion Fiberglass offers a unique solution with the Split Duct Reducing Adapter. Specially designed for field repairs where the cable cannot be removed, this reducing adapter simplifies transitions between different conduit diameters while providing durability and ease of installation. Whether you’re dealing with industrial, commercial, or utility conduit systems, this adapter brings convenience, efficiency, and reliability to your project.

Product Overview:

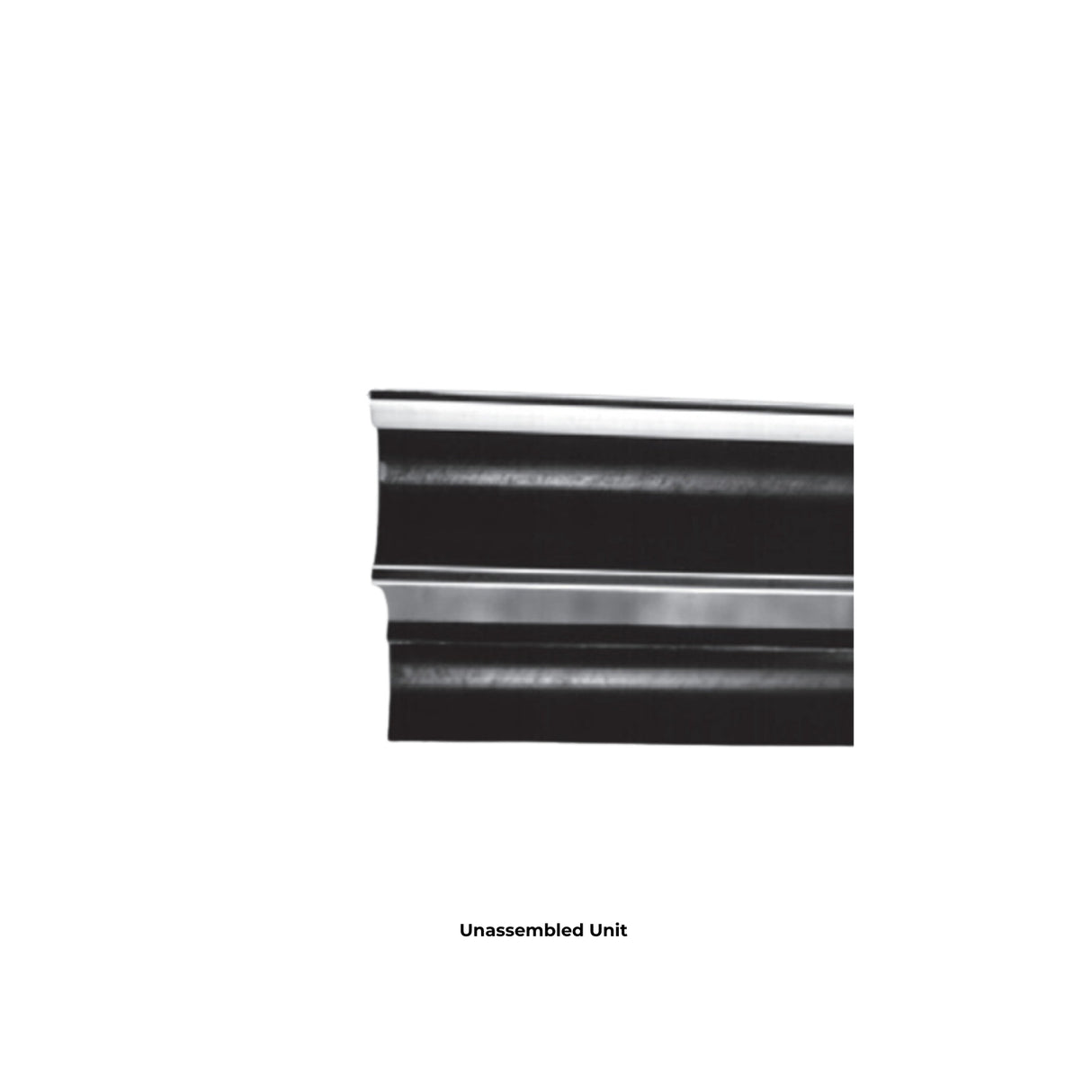

Champion Fiberglass Split Duct conduits are engineered to make even the most challenging field repairs more manageable. Unlike traditional conduits, which require significant disassembly to work around existing cables, this split duct system allows for a quick, non-invasive solution. The duct itself is split lengthwise into two halves, making it easy to position around the cable and secure in place without needing to disconnect or reroute wiring. This design makes it particularly useful for repairs and installations where continuous operation is essential, saving both time and labor costs.

Innovative Split Design for Easy Installation

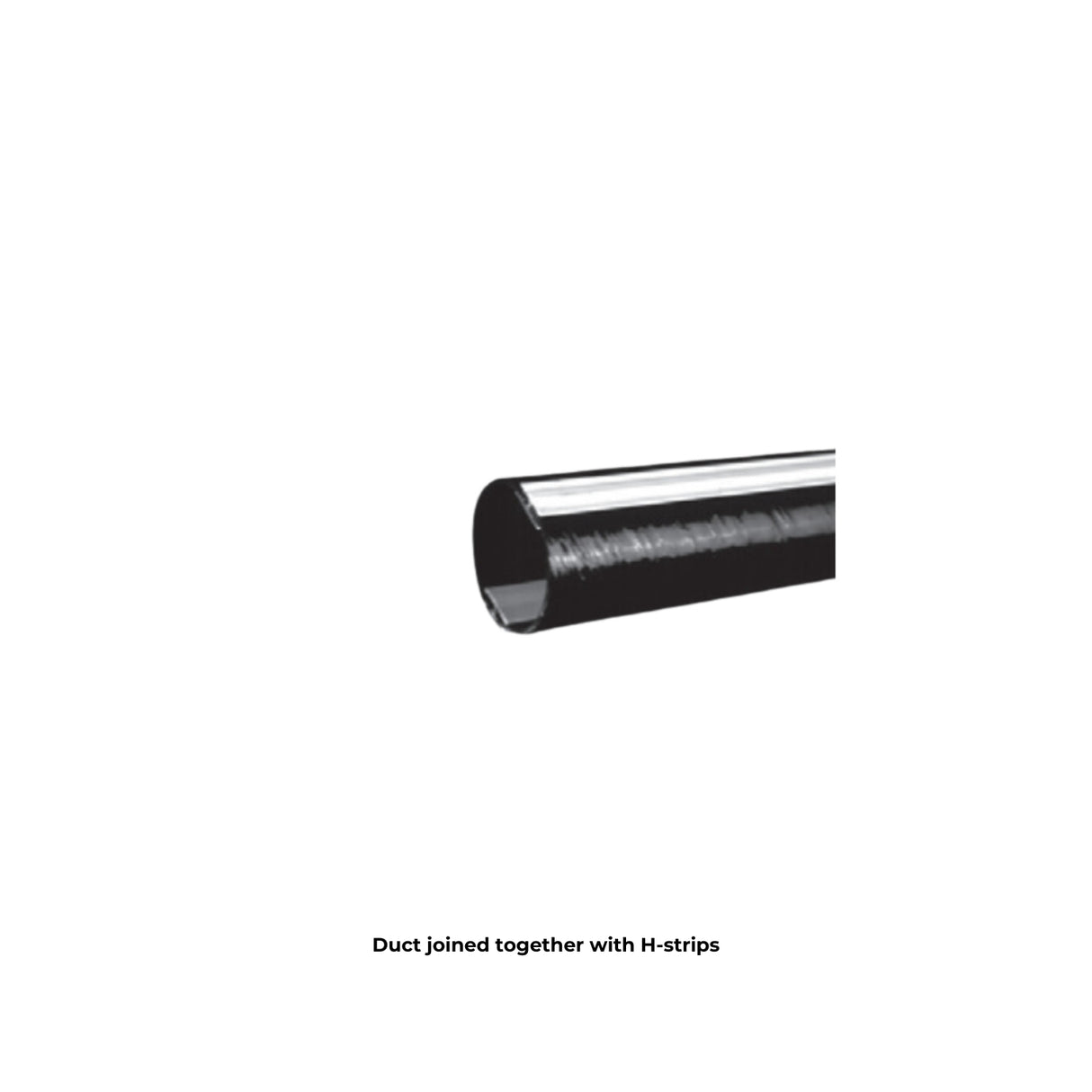

The split duct reducing adapter features a unique two-part construction that’s perfect for on-site installations and modifications. Each half of the duct snaps together along the length of the conduit, making it ideal for retrofits or repairs where cables are already installed and cannot be removed. This thoughtful design saves time by allowing technicians to perform repairs on the spot, without the need to pull or remove existing cables. Once the adapter is in place, it can be quickly secured with Champion Fiberglass’s thermoplastic H-strips, ensuring a stable, long-lasting connection between the two halves of the duct.

Secure and Reliable Connection

The Champion Fiberglass Split Duct Reducing Adapter not only simplifies repairs but also ensures durability. The two halves are joined by thermoplastic H-strips, which create a seamless bond that withstands the demands of industrial and commercial environments. For added security, cable ties should be applied every 2–3 feet along the length of the duct. These ties provide additional reinforcement, making sure the duct remains stable and aligned, even in areas subject to frequent vibrations or environmental stresses. The split duct system is designed to be as tough as it is easy to install, standing up to extreme weather conditions, UV exposure, and physical impact.

Versatility with Additional Elbows and Fittings

Champion Fiberglass understands that every project has unique needs, which is why the Split Duct system is available in a range of configurations. In addition to the standard reducing adapter, Champion Fiberglass also offers a variety of split configuration elbows and fittings to accommodate complex conduit layouts. These components are crafted with the same high-quality materials and are designed to integrate seamlessly with the split duct system. Whether you need to change conduit direction or transition between different sizes, Champion’s elbows and fittings provide a flexible, reliable solution.

Ordering Information

Please note that the H-strips and cable ties are sold separately. This allows you to customize your installation according to the specific requirements of your project. For a tailored solution, contact Champion Fiberglass directly to discuss the exact sizes and configurations you need. Their team can provide item numbers, pricing, and guidance on additional reducers, ensuring you get the precise components necessary to complete your installation to the highest standards.

Key Applications:

- Above-Ground Repairs: Ideal for situations where cables cannot be disconnected, making repairs quick and minimally invasive.

- Diameter Transitions: Allows for smooth transitions between conduits of different sizes, accommodating various setups without the need for extra parts.

- Industrial and Commercial Installations: Designed to withstand demanding environments, including outdoor conditions, industrial settings, and commercial infrastructure.

(ABOVE GROUND)

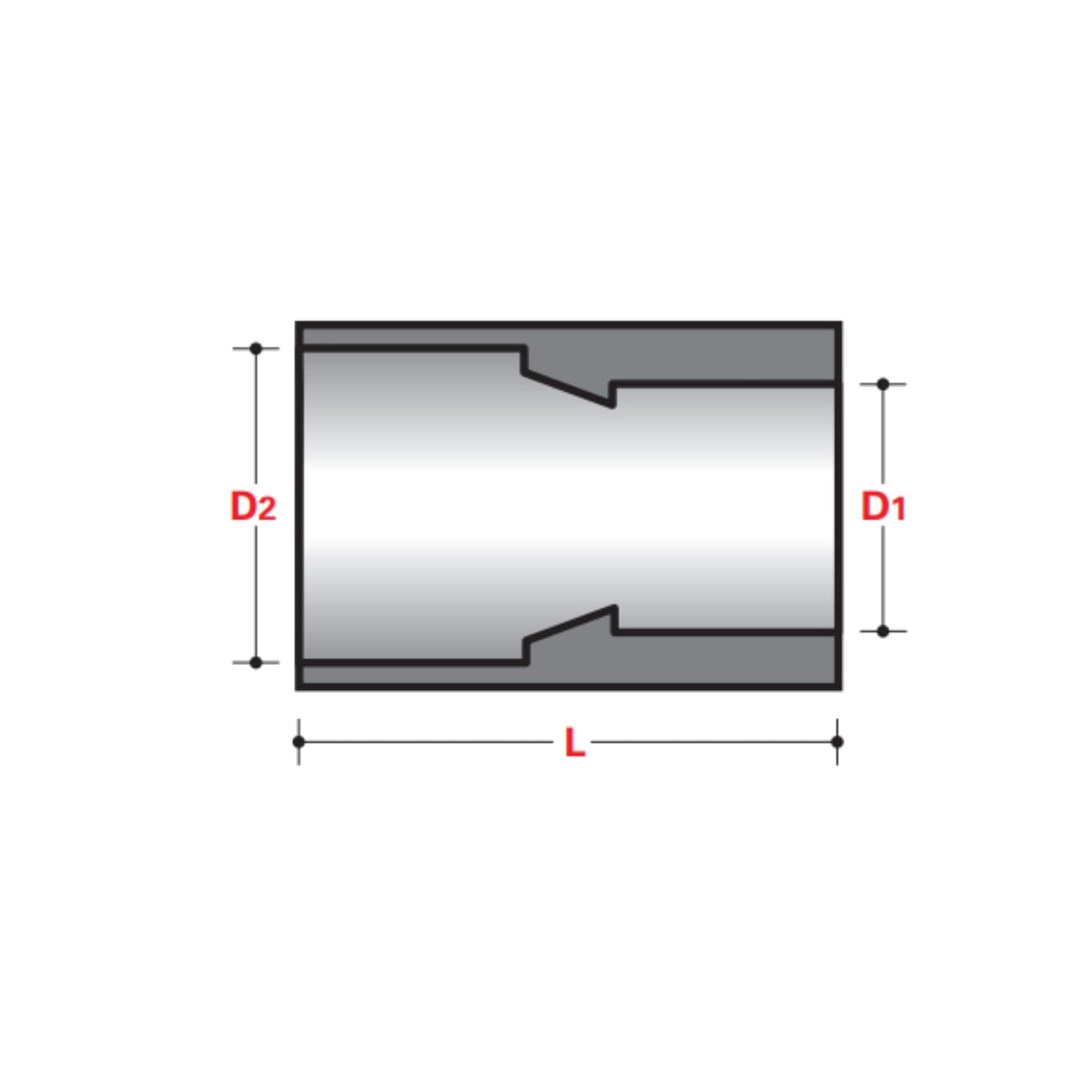

| Nominal Size | IPS Item No. (ABOVE GROUND) | D2 (mm) | D1 (inches) | D1 (mm) | L (inches) | L (mm) | Weight (LBS) | Weight (KG) |

|---|---|---|---|---|---|---|---|---|

| 3/4" SW – 1/2" SW | 07C-SW-25-05C-SW | 1.075" (27) | 0.865 | 22 | 6.5 | 165 | 0.30 | 0.14 |

| 1" SW – 1/2" SW | 10C-SW-25-05C-SW | 1.34"(34) | 0.865 | 22 | 6.5 | 165 | 0.40 | 0.18 |

| 1" SW – 3/4" SW | 10C-SW-25-07C-SW | 1.34"(34) | 1.075 | 27 | 6.5 | 165 | 0.35 | 0.16 |

| 1 1/4" SW – 3/4" SW | 12C-SW-25-07C-SW | 1.685"(42) | 1.075 | 27 | 6.5 | 165 | 0.45 | 0.20 |

| 1 1/4" SW – 1" SW | 12C-SW-25-10C-SW | 1.685"(42) | 1.34 | 34 | 6.5 | 165 | 0.40 | 0.18 |

| 1 1/2" SW – 3/4" SW | 15C-SW-25-07C-SW | 1.925"(49) | 1.075 | 27 | 6.5 | 165 | 0.50 | 0.23 |

| 1 1/2" SW – 1" SW | 15C-SW-25-10C-SW | 1.925"(49) | 1.34 | 34 | 6.5 | 165 | 0.47 | 0.21 |

| 1 1/2" SW – 1 1/4" SW | 15C-SW-25-12C-SW | 1.925"(49) | 1.685 | 42 | 6.5 | 165 | 0.37 | 0.17 |

| 2" SW – 1" SW | 20C-SW-25-10C-SW | 2.400"(61) | 1.34 | 34 | 7.5 | 191 | 0.65 | 0.32 |

| 2" SW – 1 1/4" SW | 20C-SW-25-12C-SW | 2.400"(61) | 1.685 | 42 | 7.5 | 191 | 0.55 | 0.25 |

| 2" SW – 1 1/2" SW | 20C-SW-25-15C-SW | 2.400"(61) | 1.865 | 49 | 7.5 | 191 | 0.60 | 0.27 |

| 3" SW – 2" SW | 30C-SW-25-20C-SW | 2.400"(61) | 2.4 | 61 | 7.5 | 191 | 0.80 | 0.36 |

| 4" SW – 2" SW | 40C-SW-25-20C-SW | 3.525"(89) | 2.4 | 61 | 8.5 | 216 | 0.90 | 0.41 |

| 4" SW – 3" SW | 40C-SW-25-30C-SW | 4.485"(114) | 3.525 | 89 | 8.5 | 216 | 1.10 | 0.50 |

| 5" SW – 3" SW | 50C-SW-25-30C-SW | 4.485"(114) | 3.525 | 89 | 8.5 | 216 | 1.50 | 0.68 |

| 5" SW – 4" SW | 50C-SW-25-40C-SW | 5.545"(141) | 4.485 | 114 | 8.5 | 216 | 1.50 | 0.68 |

| 6" MW – 3" SW | 60C-MW-25-30C-SW | 5.545"(141) | 3.525 | 89 | 8.5 | 216 | 1.70 | 0.77 |

| 6" MW – 4" SW | 60C-MW-25-40C-SW | 6.600"(168) | 4.485 | 114 | 8.5 | 216 | 1.90 | 0.86 |

| 6" MW – 5" SW | 60C-MW-25-50C-SW | 6.652"(169) | 5.545 | 141 | 8.5 | 216 | 1.90 | 0.86 |