STRAIGHT SOCKET (XW) - ABOVE GROUND

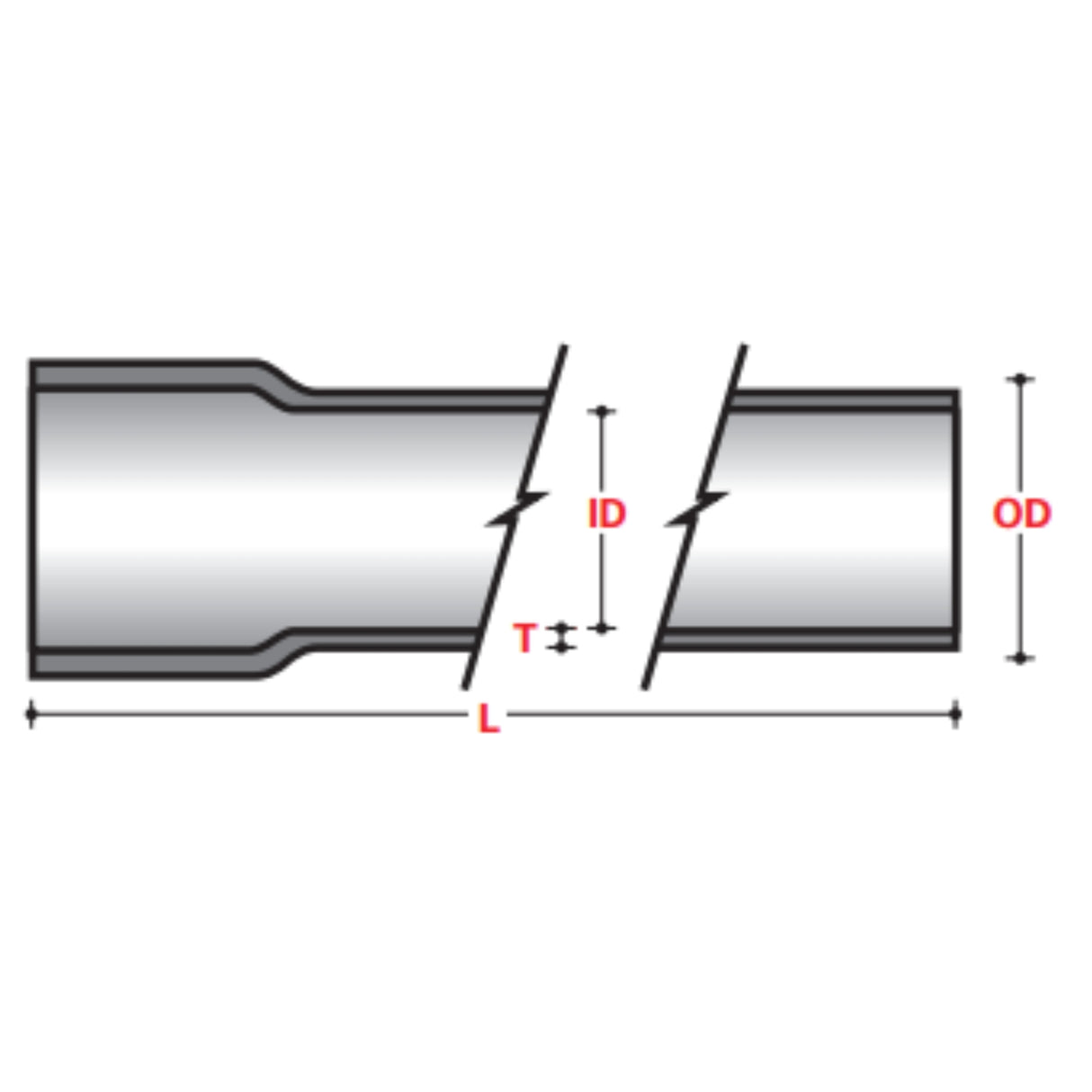

The XW Conduit with Straight Socket is engineered for exceptional strength, corrosion resistance, and reliable performance in demanding environments. This ID-sized (Inside Diameter) conduit boasts an impressive 0.250-inch wall thickness, specifically designed to meet the rigorous needs of Class I, Division 2 hazardous locations, and other installations where extreme durability and impact resistance are crucial.

Key Features and Benefits:

- Class I, Division 2 Compliance: Built to perform in hazardous environments, the XW Conduit meets stringent safety standards, making it ideal for locations at risk of explosive gases or volatile particles. The robust construction ensures high protection levels in these demanding settings, commonly seen in industries such as wastewater treatment and chemical processing.

- Superior Impact Strength: Constructed with an extra-heavy wall, this conduit has been shown to stop a .45 caliber bullet from 20 feet away. This incredible strength makes it an ideal solution for locations prone to physical damage, as it can withstand even the most severe impact risks, ensuring a long-lasting protective barrier for internal wiring or fiber-optic cables.

- Corrosion-Resistant Design: In addition to impact strength, the XW conduit is corrosion-resistant, making it perfect for outdoor and industrial environments where exposure to moisture, chemicals, and other corrosive elements is a constant concern. Wastewater treatment plants, for example, benefit from the conduit’s resistance to chemical wear, enhancing longevity and reducing the need for frequent maintenance or replacement.

- Utility-Grade Protection for Fiber-Optic Cabling: Utility companies trust the XW conduit to protect sensitive fiber-optic cables, especially in above-ground or under-bridge installations where durability is paramount. This conduit acts as a shield against environmental and physical stressors, ensuring the integrity of critical communication and power lines.

- NEC Article 355.10F Compliance: As stipulated in NEC Article 355.10F, the XW conduit is approved for use in areas where extra protection against physical damage is required. It’s an essential choice for installations in exposed areas, including industrial and municipal sites, where the risk of impact or exposure to harsh elements is significant.

Technical Specifications:

- Conduit Type: XW (Extra Heavy Wall)

- Connection: Straight Socket

- Wall Thickness: 0.250 inches

- Compliance: Class I, Division 2, NEC Article 355.10F

- Protection Level: Impact-resistant, corrosion-resistant, bullet-resistant (.45 caliber from 20 ft)

Applications:

- Wastewater Treatment Facilities: Perfect for corrosive and high-risk environments where safety and longevity are critical.

- Utility Infrastructure: Ideal for protecting fiber-optic cables and wiring in above-ground installations or under bridges, where environmental durability is essential.

- Hazardous Locations: Effective in hazardous locations classified as Class I, Division 2, offering robust protection in settings at risk of gas or dust explosions.

- Heavy-Duty Industrial Sites: Recommended for areas exposed to frequent impact risks, from construction zones to chemical processing plants.

For projects that demand unparalleled strength, longevity, and safety, the XW Conduit with Straight Socket connection is a top choice. Combining bullet-stopping strength, corrosion resistance, and compliance with Class I, Division 2 standards, this conduit is designed to safeguard sensitive cabling and electrical systems in the most challenging conditions. Wastewater facilities, utility companies, and industrial sites all trust XW conduit for its proven ability to withstand both environmental and physical stresses.

| Nominal Size | XW Item No (Above Ground) | UL/CSA Listed | Outside Diameter (Average) | Outside Diameter (Tolerance) | Min. Inside Diameter | Nominal Wall Thickness | Length (L) | Weight Lbs/Ft | Weight Kg/M |

|---|---|---|---|---|---|---|---|---|---|

| 3/4" (19) | 07C-XW-10S | Yes | 1.410" (36) | +0.056" (1.4) / -0.036" (0.9) | 0.910" (23) | .25" (6) | 10 ft (3 m) | 0.61 | 0.91 |

| 1" (25) | 10C-XW-10S | Yes | 1.675" (43) | +0.056" (1.4) / -0.036" (0.9) | 1.175" (30) | .25" (6) | 10 ft (3 m) | 0.68 | 1.01 |

| 1-1/4" (32) | 12C-XW-20-S | Yes | 2.020" (51) | +0.056" (1.4) / -0.036" (0.9) | 1.520" (39) | .25" (6) | 20 ft (6.1 m) | 0.82 | 1.22 |

| 1-1/2" (38) | 15C-XW-20-S | Yes | 2.260" (57) | +0.056" (1.4) / -0.036" (0.9) | 1.760" (45) | .25" (6) | 20 ft (6.1 m) | 1.18 | 1.76 |

| 2" (51) | 20D-XW-20-S | Yes | 2.500" (64) | +0.056" (1.4) / -0.036" (0.9) | 2.000" (51) | .25" (6) | 20 ft (6.1 m) | 1.26 | 1.88 |

| 2-1/2" (64) | 25D-XW-20-S | Yes | 3.000" (76) | +0.056" (1.4) / -0.036" (0.9) | 2.500" (64) | .25" (6) | 20 ft (6.1 m) | 1.54 | 2.29 |

| 3" (76) | 30D-XW-20-S | Yes | 3.500" (89) | +0.056" (1.4) / -0.036" (0.9) | 3.000" (76) | .25" (6) | 20 ft (6.1 m) | 1.82 | 2.71 |

| 3-1/2" (89) | 35D-XW-20-S | Yes | 4.000" (102) | +0.056" (1.4) / -0.036" (0.9) | 3.500" (89) | .25" (6) | 20 ft (6.1 m) | 2.10 | 3.13 |

| 4" (102) | 40D-XW-20-S | Yes | 4.500" (114) | +0.056" (1.4) / -0.036" (0.9) | 4.000" (102) | .25" (6) | 20 ft (6.1 m) | 2.38 | 3.54 |

| 5" (127) | 50D-XW-20-S | Yes | 5.500" (140) | +0.056" (1.4) / -0.036" (0.9) | 5.000" (127) | .25" (6) | 20 ft (6.1 m) | 2.94 | 4.38 |

| 6" (152) | 60D-XW-20-S | Yes | 6.500" (165) | +0.056" (1.4) / -0.036" (0.9) | 6.000" (152) | .25" (6) | 20 ft (6.1 m) | 3.50 | 5.21 |

| 8" (203) | 80C-XW-20-S | – | 8.900" (226) | +0.056" (1.4) / -0.036" (0.9) | 8.400" (213) | .25" (6) | 20 ft (6.1 m) | 4.80 | 7.14 |

| 10" (254) | 100D-XW-20-S | – | 10.500" (267) | +0.056" (1.4) / -0.036" (0.9) | 10.000" (254) | .25" (6) | 20 ft (6.1 m) | 5.74 | 8.54 |

| 12" (305) | 120D-XW-20-S | – | 12.500" (318) | +0.056" (1.4) / -0.036" (0.9) | 12.000" (305) | .25" (6) | 20 ft (6.1 m) | 6.86 | 10.21 |