Series 865 Extra Heavy Transition Fitting | ID-Controlled Weld-On | A53/A106

$2,004.26

Unit price

/

Select Option

Series 865 Extra Heavy ID Controlled Weld-On (A53/A106) — Product Overview

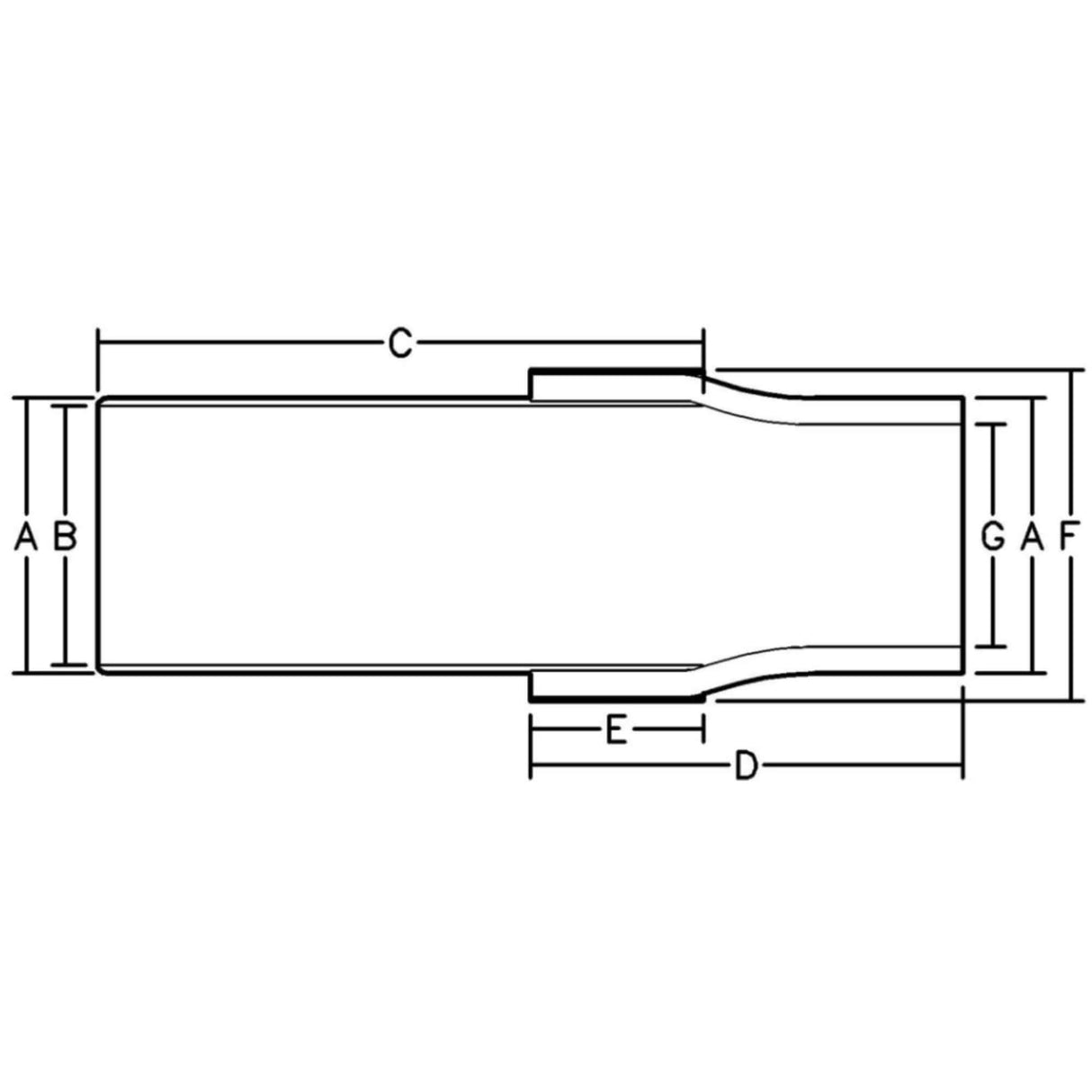

Poly-Cam Series 865 Extra Heavy ID-Controlled Weld-On fittings create a smooth interior transition between steel pipe and HDPE, eliminating internal edges that could damage cleaning pigs. The multi-level barb system and compression ring work together to provide a secure, leak-resistant connection. All weld-on components are epoxy coated for long-term corrosion resistance and durability in the field.

Key Features

- Smooth Interior Flow: Prevents pig obstruction and reduces turbulence.

- Multi-Level Barb Seal: Ensures a strong, leak-resistant steel-to-HDPE transition.

- Compression Ring Support: Epoxy-coated carbon steel; stainless steel options available.

- Custom Engineered Fit: Designed for specific steel grades and HDPE pipe types.

- Durable Epoxy Coating: Enhances corrosion protection in demanding environments.

Applications

- Water, gas, and chemical systems

- Pipelines requiring pigging operations

- Reliable transitions between steel and HDPE

Material Options

- Standard: A53B ERW Carbon Steel / A106 Seamless Carbon Steel

- Optional: X42, X52, X60, X65, X70, API 5L, NACE MR0175, A333 Grade 6

- Stainless Steel: 304 or 316 stainless steel (availability varies)

Documentation

- Series 865 SDR7 Submittal PDF

- Series 865 SDR9 Submittal PDF

- Series 865 SDR11 Submittal PDF

- Series 865 SDR17 Submittal PDF

Order Guide — SDR 7

| Size | HDPE/Steel O.D. (A) | Steel I.D. (B) | Steel L (C) | HDPE L (D) | Ring L (E) | Ring O.D. (F) | HDPE I.D. (G) |

|---|---|---|---|---|---|---|---|

| 2 | 2.375 | 1.939 | 12 | 24 | 3.5 | ~3.08 | 1.686 |

| 2.5 | 2.875 | 2.323 | 14 | 24 | 3.5 | N/A | N/A |

| 3 | 3.5 | 2.9 | 14 | 24 | 5 | ~4.47 | 2.44 |

| 4 | 4.5 | 3.826 | 14 | 24 | 5.5 | ~5.88 | 3.137 |

| 6 | 6.625 | 5.761 | 20 | 30 | 8 | ~8.6 | 4.619 |

| 8 | 8.625 | 7.625 | 22 | 30 | 10 | ~11.1 | 6.013 |

| 10 | 10.75 | 9.75 | 26 | 40 | 12 | ~14.0 | 7.494 |

| 12 | 12.75 | 11.75 | 28 | 40 | 12 | ~16.6 | 8.889 |

| 14 | 14 | 13 | 28 | 40 | 12 | ~18.2 | 9.76 |

| 16 | 16 | 15 | 28 | 48 | 14 | ~20.8 | 11.154 |

| 18 | 18 | 17 | 28 | 48 | 14 | ~23.4 | 12.549 |

| 20 | 20 | 19 | 28 | 48 | 15 | ~26.0 | 13.943 |

| 24 | 24 | 23 | 28 | 48 | 15 | ~31.1 | 16.731 |

Order Guide — SDR 9

| Size | HDPE/Steel O.D. (A) | Steel I.D. (B) | Steel L (C) | HDPE L (D) | Ring L (E) | Ring O.D. (F) | HDPE I.D. (G) |

|---|---|---|---|---|---|---|---|

| 2 | 2.375 | 1.939 | 12 | 24 | 3.5 | ~2.95 | 1.815 |

| 2.5 | 2.875 | 2.323 | 14 | 24 | 3.5 | ~3.54 | 2.198 |

| 3 | 3.5 | 2.9 | 14 | 24 | 5 | ~4.29 | 2.675 |

| 4 | 4.5 | 3.826 | 14 | 24 | 5.5 | ~5.64 | 3.44 |

| 6 | 6.625 | 5.761 | 20 | 30 | 8 | ~8.2 | 5.065 |

| 8 | 8.625 | 7.625 | 22 | 30 | 10 | ~10.7 | 6.594 |

| 10 | 10.75 | 9.75 | 26 | 40 | 12 | ~13.4 | 8.219 |

| 12 | 12.75 | 11.75 | 28 | 40 | 12 | ~15.9 | 9.746 |

| 14 | 14 | 13 | 28 | 40 | 12 | ~17.4 | 10.701 |

| 16 | 16 | 15 | 28 | 48 | 14 | ~19.9 | 12.231 |

| 18 | 18 | 17 | 28 | 48 | 14 | ~22.4 | 13.76 |

| 20 | 20 | 19 | 28 | 48 | 15 | ~24.9 | 15.289 |

| 24 | 24 | 23 | 28 | 48 | 15 | ~29.8 | 18.346 |

Order Guide — SDR 11

| Size | HDPE/Steel O.D. (A) | Steel I.D. (B) | Steel L (C) | HDPE L (D) | Ring L (E) | Ring O.D. (F) | HDPE I.D. (G) |

|---|---|---|---|---|---|---|---|

| 0.75 | 1.05 | 0.742 | 11 | 8 | 1.57 | ~1.84 | 0.85 |

| 2 | 2.375 | 1.939 | 12 | 24 | 3.5 | ~2.84 | 1.917 |

| 2.5 | 2.875 | 2.323 | 14 | 24 | 3.5 | ~3.41 | 2.321 |

| 3 | 3.5 | 2.9 | 14 | 24 | 5 | ~4.14 | 2.826 |

| 4 | 4.5 | 3.826 | 14 | 24 | 5.5 | ~5.44 | 3.633 |

| 6 | 6.625 | 5.761 | 20 | 30 | 8 | ~8.0 | 5.349 |

| 8 | 8.625 | 7.625 | 22 | 30 | 10 | ~10.3 | 6.963 |

| 10 | 10.75 | 9.75 | 26 | 40 | 12 | ~12.9 | 8.679 |

| 12 | 12.75 | 11.75 | 28 | 40 | 12 | ~15.3 | 9.746 |

| 14 | 14 | 13 | 28 | 40 | 12 | ~16.8 | 11.301 |

| 16 | 16 | 15 | 28 | 48 | 14 | ~18.1 | 12.915 |

| 18 | 18 | 17 | 28 | 48 | 14 | ~20.4 | 14.532 |

| 20 | 20 | 19 | 28 | 48 | 15 | ~24.0 | 16.146 |

| 24 | 24 | 23 | 28 | 48 | 15 | ~28.8 | 19.374 |

Order Guide — SDR 17

| Size | HDPE/Steel O.D. (A) | Steel I.D. (B) | Steel L (C) | HDPE L (D) | Ring L (E) | Ring O.D. (F) | HDPE I.D. (G) |

|---|---|---|---|---|---|---|---|

| 2 | 2.375 | 1.939 | 12 | 24 | 3.5 | ~2.68 | 2.078 |

| 2.5 | 2.875 | 2.323 | 14 | 24 | 3.5 | N/A | N/A |

| 3 | 3.5 | 2.9 | 14 | 24 | 5 | ~3.90 | 3.063 |

| 4 | 4.5 | 3.826 | 14 | 24 | 5.5 | ~5.14 | 3.938 |

| 6 | 6.625 | 5.761 | 20 | 30 | 8 | ~7.5 | 5.798 |

| 8 | 8.625 | 7.625 | 22 | 30 | 10 | ~9.7 | 7.55 |

| 10 | 10.75 | 9.75 | 26 | 40 | 12 | ~12.2 | 9.41 |

| 12 | 12.75 | 11.75 | 28 | 40 | 12 | ~14.4 | 11.16 |

| 14 | 14 | 13 | 28 | 40 | 12 | ~15.9 | 12.253 |

| 16 | 16 | 15 | 28 | 48 | 14 | ~18.1 | 14.005 |

| 18 | 18 | 17 | 28 | 48 | 14 | ~20.4 | 15.755 |