Standard Machine Grooved Transition Fitting | IPS | HDPE to Steel | SDR 7–17 | 125–335 PSI

Standard Machine Grooved Transition Fitting | IPS | HDPE to Steel | SDR 7–17 | 125–335 PSI

Integrity Fusion Standard Machine Grooved Transition Fittings provide a robust, corrosion-resistant connection between HDPE and grooved-end steel piping systems. Each fitting is precision-machined with an internally beveled groove for a secure mechanical joint that operates at the maximum allowable operating pressure (MAOP) of the connected pipe SDR. Built with epoxy-coated carbon steel collars, these transitions ensure full HDPE coverage through the collar for a piggable, corrosion-free bore that protects against electrochemical and environmental wear.

Designed for use in municipal, industrial, geothermal, mining, and process piping applications, these fittings are compliant with ASTM D3261, F1598, F1599, AWWA C901/C906, and NSF/ANSI 61 & 372 standards, providing long-term reliability and strength in both pressure and non-pressure systems.

Key Features & Benefits

- Precision Grooved Steel Collar — Internally machined and beveled design ensures a secure mechanical joint and easy coupling alignment.

- Full HDPE Extension — Provides complete corrosion protection and a smooth, piggable internal bore.

- Pressure Rated for SDR 7–17 — Rated from 125 PSI (SDR 17) up to 335 PSI (SDR 7) depending on pipe wall thickness.

- Epoxy-Coated Carbon Steel — Durable A53/API-5 carbon steel collar with epoxy coating resists corrosion and abrasion.

- Industry Compliant — Meets ASTM D3261, F1598, F1599, AWWA C901/C906, and NSF/ANSI 61 & 372 standards.

Typical Applications

- Municipal and Industrial Water Systems

- Geothermal and Process Piping

- Mining and Slurry Transport Lines

- Wastewater and Landfill Infrastructure

- Irrigation and Dredging Systems

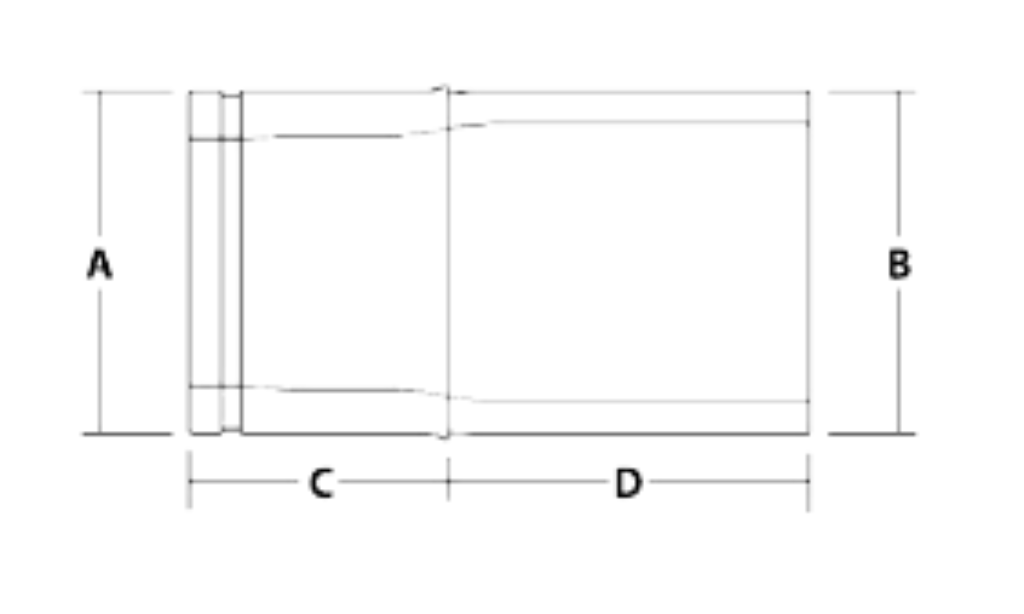

Product Dimensions & Specifications

| Size (IPS) | SDR | MAOP (PSI @ 73.4°F) | Collar Material | Collar Diameter (in.) | Steel Collar Length (in.) | Exposed HDPE (in.) | Weight (lbs.) | Item Code |

|---|---|---|---|---|---|---|---|---|

| 2” | 11 / 9 | 200 / 255 | Epoxy-Coated Steel | 3.00 | 4.00 | 4.00 | 4 / 5 | 400565 / 400569 |

| 3” | 11 / 9 / 7 | 200 / 255 / 335 | Epoxy-Coated Steel | 3.50 | 4.00 | 4.00 | 7–8 | 400544 / 400546 / 400545 |

| 4” | 11 / 9 / 7 | 200 / 255 / 335 | Epoxy-Coated Steel | 4.50 | 4.00 | 4.00 | 9–10 | 400547 / 400549 / 400548 |

| 6” | 11 / 9 / 7 / 17 | 200 / 255 / 335 / 125 | Epoxy-Coated Steel | 6.63 | 5.00 | 8.00 | 14–16 | 400550 / 400553 / 400552 / 400551 |

| 8” | 11 / 9 / 7 / 17 | 200 / 255 / 335 / 125 | Epoxy-Coated Steel | 8.63 | 7.00 | 8.00 | 21–24 | 400554 / 400557 / 400556 / 400555 |

| 10” | 11 / 9 / 17 | 200 / 255 / 125 | Epoxy-Coated Steel | 10.75 | 8.00 | 8.00 | 30–35 | 400558 / 400562 / 400559 |

| 12” | 11 / 17 | 200 / 125 | Epoxy-Coated Steel | 12.75 | 9.00 | 9.00 | 40–48 | 400560 / 400561 |

Installation Note: Verify groove alignment before coupling installation. Use manufacturer-approved gaskets and couplings for best performance. Always pressure test before backfilling.