Molded HDPE Reducer | IPS & DIPS | SDR 7–17 | 125–335 PSI

Molded HDPE Reducer | IPS & DIPS | SDR 7–17 | 125–335 PSI | Integrity Fusion

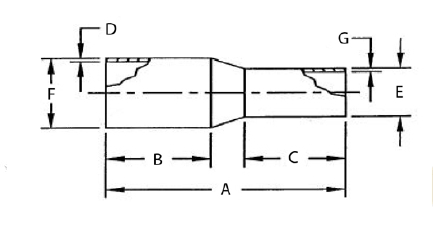

Integrity Fusion Molded HDPE Reducers provide smooth, pressure-rated transitions between pipes of different diameters with no internal obstructions to restrict flow. These fully molded fittings use high-performance PE4710/PE100 resin and are engineered to maintain both hydraulic efficiency and long-term structural integrity in modern piping systems.

Designed for IPS and DIPS polyethylene pipelines, these reducers are available across SDR 7, 9, 11, and 17 with pressure ratings from 125–335 PSI (at 73.4°F). Uniform wall thickness, precision molding, and generous stab lengths support reliable butt-fusion joints in municipal, industrial, landfill, oil & gas, and mining applications.

Key Features & Benefits

- PE4710/PE100 Resin: High strength, long service life, and excellent pressure performance.

- Fully Molded Construction: Eliminates fabricated weld seams for consistent dimensions and fit-up.

- Bead-Controlled Interior: Smooth bore design minimizes flow restriction and pressure loss.

- Uniform Wall Thickness: Even stress distribution for demanding pressure and cyclic service.

- Broad SDR Coverage: Available in SDR 7, 9, 11, and 17 to match common PE piping systems.

- IPS & DIPS Compatibility: Configurations for both IPS and DIPS mains and branch lines.

- Code-Compliant: Manufactured to meet ASTM, AWWA, NSF, and FM requirements for potable water and gas.

Applications

Potable Water • Reclaimed Water • Natural Gas & Propane Distribution • Industrial Fluids • Landfill Systems • Mining & Slurry Lines • Geothermal & Energy Distribution

Certifications & Compliance

- Manufactured in the USA – Build America, Buy America (BABA) compliant.

- ASTM D2513 & ASTM D3261: Standard specifications for PE gas and water fittings.

- AWWA C901 / C906: PE pressure pipe and fittings for water and wastewater service.

- NSF/ANSI 61 & 372: Certified for potable water contact and low-lead compliance.

- FM Approved: Selected sizes approved for fire protection and other pressure applications.

Available SDRs & Size Ranges

- SDR 7 (335 PSI): IPS reducers from 3" × 2" up to 8" × 6".

- SDR 9 (255 PSI): IPS reducers from 3" × 2" up to 8" × 6"; DIPS reducers from 10" × 6" up to 12" × 8".

- SDR 11 (200 PSI): IPS reducers from 1" × 3/4" up to 12" × 10"; DIPS reducers from 6" × 4" up to 12" × 8".

- SDR 17 (125 PSI): IPS reducers from 3" × 2" up to 12" × 10"; DIPS reducers from 8" × 6" up to 12" × 8".

Select the appropriate Large × Small reducer size (IPS or DIPS) and matching SDR/pressure rating from the product dropdown above.

Specification Summary

Detailed dimensional data – including overall length, stab depths, wall thicknesses, and reducer weights for each size and SDR – are provided in the downloadable Molded Reducer Dimension Sheet linked above. Always verify pipe OD, SDR, and pressure class when selecting molded reducers for a specific project.