Series 517 HDPE Blind Flange with Female NPT

Series 517 HDPE Blind Flange with Female NPT — Product Overview

Designed to terminate or test piping systems with absolute reliability, the Series 517 HDPE Blind Flange with Female NPT combines hydraulic compression technology and a reinforced barbed design for leak-free performance. Ideal for industrial, municipal, and utility applications, this fitting ensures long-term integrity under pressure fluctuations and thermal stress. Available in sizes from 0.5" to 2" NPT, it meets ANSI/ASME B1.20.1 standards and includes a compression ring for added stability.

Key Features & Benefits

- Blind Flange Functionality: Seals pipe ends securely while allowing future system expansion or pressure testing.

- Pressure-Activated Seal: Multi-level barbs tighten under internal pressure, preventing leaks even during thermal contraction.

- Lead-Free Materials: C954 Bronze option complies with environmental and potable water safety standards.

- 50-Year Performance: Built with a 2:1 safety factor at 73.4°F, certified to ASTM 1598/1599 and ARRA requirements.

Technical Specifications

- Sizes: 0.5”–2” NPT (ANSI/ASME B1.20.1 compliant).

- HDPE Pipe: ASTM D3350 (PE3408/PE4710), F714, D3035. Tensile strength: 3,200–3,500 psi; ESCR ≥5,000 hours (zero failures).

- Melt Index: ≤0.15 g/10 min (ASTM D1238).

Installation Guidelines

- Use smooth-jawed or Poly-Cam wrenches—avoid pipe wrenches to prevent damage.

- Apply Teflon tape or pipe sealant to threads for airtight connections.

- Pressure-test joints before backfilling; compact soil to avoid shifts.

- Follow Plastic Pipe Institute’s butt fusion procedures for HDPE welds.

Material & Compliance

- Fittings: 304/316 Stainless Steel (ASTM A249/A269) or lead-free C954 Bronze.

- HDPE: Density ≥0.955 g/cm³ (ASTM D1505), certified for NSF 61 and UL 262.

- Certifications: Available upon request.

Warranty: 1 year post-installation completion.

Ensure system integrity and compliance with Poly-Cam’s Series 517—engineered for durability, safety, and seamless end-of-line sealing. Contact us for certifications or technical assistance.

Order Guide

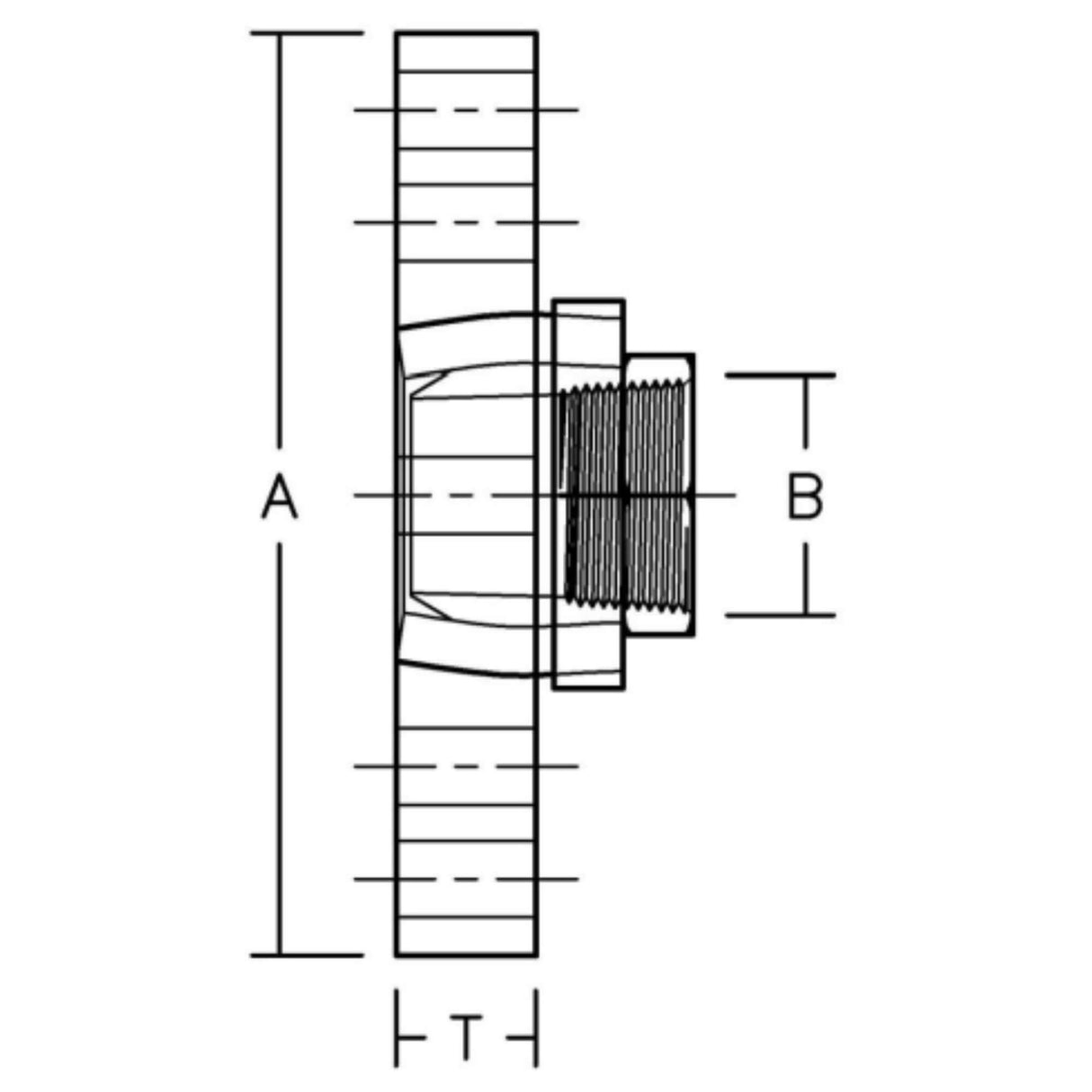

| Nominal Size (ln.) | Flange O.D. A | Female Thread Outlet Nominal Size B |

Thickness T | # of Bolts | Bolt Hole Diameter |

|---|---|---|---|---|---|

| 2 | 6 | 0.5-0.75 | 1/2" | 4 | 0.75" |

| 3 | 7.5 | 0.5-1 | 1/2" | 4 | 0.75" |

| 4 | 9 | 0.5-1.66 | 1/2" | 4 | 0.75" |

| 6 | 11 | 0.5-2.375 | 1/2" | 8 | 0.88" |

| 8 | 13.5 | 0.5-2.375 | 1/2" | 8 | 0.88" |

| 10 | 16 | 0.5-2.375 | 1/2" | 12 | 1" |

| 12 | 19 | 0.5-2.375 | 1/2" | 12 | 1" |

| 14 | 21 | 0.5-2.375 | 1/2" | 12 | 1.13" |

| 16 | 23.5 | 0.5-2.375 | 1/2" | 16 | 1.13" |

| 18 | 25 | 0.5-2.375 | 1/2" | 16 | 1.25" |

| 20 | 27.5 | 0.5-2.375 | 1/2" | 20 | 1.25" |

| 22 | 29.5 | 0.5-2.375 | 1/2" | 20 | 1.38" |

| 24 | 32 | 0.5-2.375 | 1/2" | 20 | 1.38" |