Heavy Duty Male NPT Transition Fitting | IPS | HDPE to Steel | SDR 7–17 | 125–335 PSI

Heavy Duty Male NPT Transition Fitting | IPS | HDPE to Steel | SDR 7–17 | 125–335 PSI

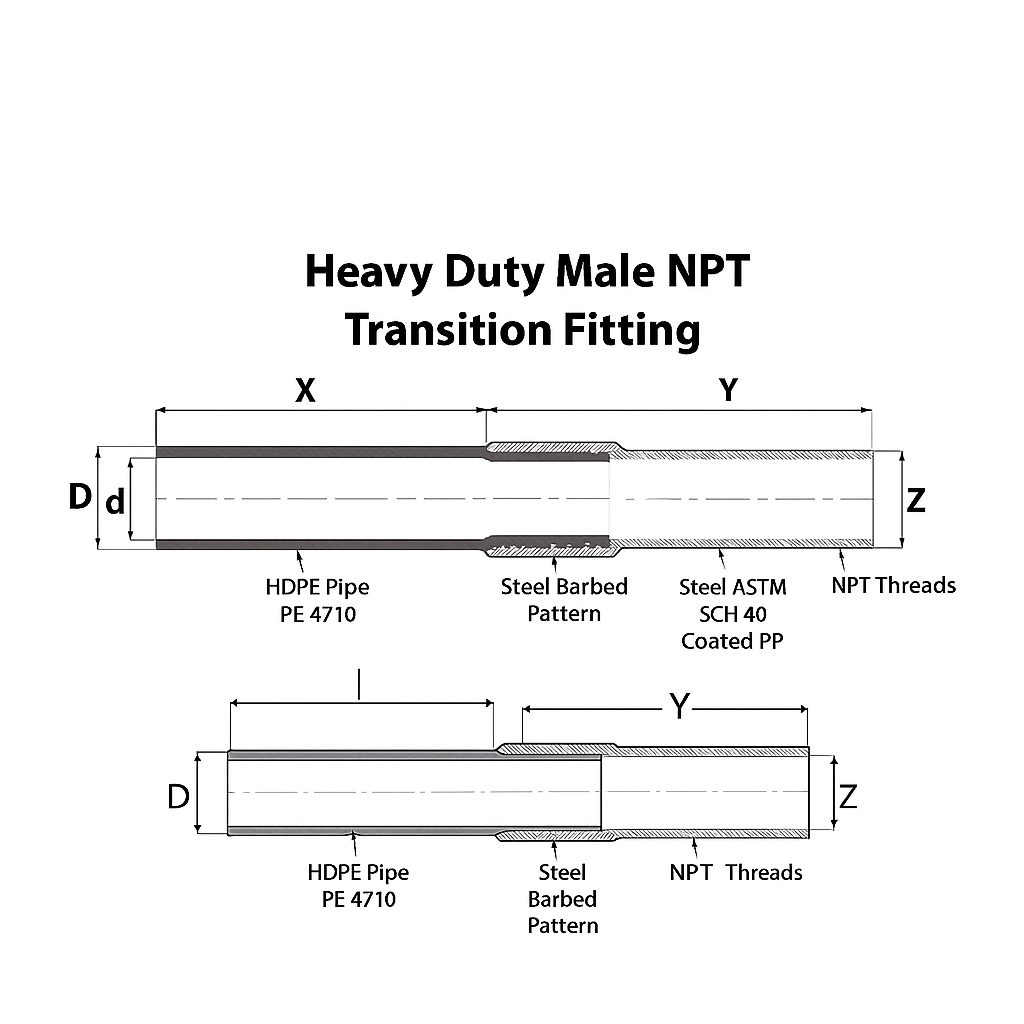

Integrity Fusion Heavy Duty Male NPT Transition Fittings provide a secure, high-strength mechanical transition between HDPE and steel piping systems. Each fitting features a heavy-duty carbon steel collar with an internal and external epoxy coating for superior corrosion protection and long-term durability. The HDPE extension passes completely through the steel collar, creating a smooth, piggable bore and maintaining full protection against electrochemical and environmental corrosion.

Designed for SDR 7 through SDR 17 HDPE systems, these fittings are precision-machined to ANSI/ASME B1.20.1 standards and rated up to 335 PSI. Commonly used in municipal, industrial, geothermal, and mining applications, Integrity Fusion’s heavy-duty transition fittings deliver reliable, leak-free performance under demanding conditions.

Key Features & Benefits

- Heavy-Duty NPT Threads — Machined to ANSI/ASME B1.20.1 for precise, pressure-rated mechanical joints.

- Full HDPE Extension — Maintains a corrosion-free, piggable bore through the entire steel collar.

- Epoxy-Coated Steel Collar — Provides internal and external corrosion resistance for long-term service life.

- Pressure Rated for SDR 7–17 — Supports MAOP from 125 PSI (SDR 17) up to 335 PSI (SDR 7).

- Industry Compliant — Meets ASTM D3261, F1598, F1599, AWWA C901/C906, and NSF/ANSI 61 & 372 standards.

Typical Applications

- Municipal water and wastewater systems

- Industrial and process piping installations

- Geothermal, landfill, and mining systems

- Irrigation and environmental containment projects

Product Dimensions & Specifications

| Nominal Size | SDR | MAOP (PSI @73.4°F) | Material | Collar Length (in.) | HDPE Length (in.) | HDPE OD (in.) | Weight (lbs.) | Item Code |

|---|---|---|---|---|---|---|---|---|

| 2” IPS | 7 | 335 | Epoxy-Coated Steel | 5.84 | 9.36 | 2.375 | 2.8 | 400710 |

| 2” IPS | 9 | 255 | Epoxy-Coated Steel | 5.84 | 9.36 | 2.375 | 2.6 | 400711 |

| 2” IPS | 11 | 200 | Epoxy-Coated Steel | 5.84 | 9.36 | 2.375 | 2.4 | 400709 |

| 3” IPS | 7 | 335 | Epoxy-Coated Steel | 6.80 | 8.87 | 3.500 | 6.0 | 400713 |

| 3” IPS | 9 | 255 | Epoxy-Coated Steel | 6.80 | 8.87 | 3.500 | 5.5 | 400714 |

| 3” IPS | 11 | 200 | Epoxy-Coated Steel | 6.80 | 8.87 | 3.500 | 5.2 | 400712 |

| 4” IPS | 7 | 335 | Epoxy-Coated Steel | 7.39 | 11.43 | 4.500 | 10.7 | 400716 |

| 4” IPS | 9 | 255 | Epoxy-Coated Steel | 7.39 | 11.43 | 4.500 | 9.9 | 400717 |

| 4” IPS | 11 | 200 | Epoxy-Coated Steel | 7.39 | 11.43 | 4.500 | 8.3 | 400715 |

| 6” IPS | 7 | 335 | Epoxy-Coated Steel | 7.70 | 10.54 | 6.625 | 21.3 | 400735 |

| 6” IPS | 9 | 255 | Epoxy-Coated Steel | 7.70 | 10.54 | 6.625 | 19.6 | 400734 |

| 6” IPS | 11 | 200 | Epoxy-Coated Steel | 7.70 | 10.54 | 6.625 | 18.3 | 400733 |

| 6” IPS | 17 | 125 | Epoxy-Coated Steel | 7.70 | 10.54 | 6.625 | 17.1 | 400736 |

Installation Note: Apply Teflon tape or approved sealant to threads. Hand tighten, then use two strap wrenches only — never pipe wrenches. Always pressure test before backfilling.