Reverse Threaded Barbed Couplings | Aluminum

The US Coupler Aluminum Reverse Threaded Barbed Couplings are designed for efficient, reliable, and airtight connections in various innerduct applications. Combining the advantages of traditional reverse thread couplings with the enhanced sealing capability of barbed ring technology, these couplings provide a strong, secure connection without the need for special installation tools.

Key Features:

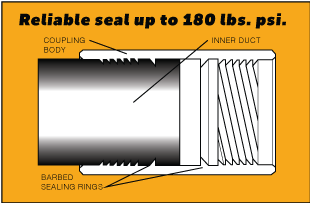

- Airtight Seal: These couplings incorporate the same dependable full circumference seal used in barbed ring compression couplings, ensuring a positive, airtight connection up to 180 lbs. psi. This feature is critical for maintaining the integrity of the duct system under pressure.

- Easy Installation: Unlike traditional compression couplings that require a coupling press, these reverse thread barbed couplings can be installed just like any ordinary reverse thread coupling. Thanks to the special wide pitch, fast traveling thread, only 10 complete turns are needed for installation, significantly reducing labor time.

- Versatile Application: The outside diameters of these couplings are designed to be small enough for easy pulling into primary ducts or through plow chutes, making them ideal for a wide range of installation environments. They also permit tensile loading as high as conventional reverse couplings.

- Custom Sizing Available: As a machined product, these couplings can be sized to match the exact outside diameter of any innerduct, accommodating the .012-.015 manufacturing tolerances typically allowed in innerduct production. Custom sizes are available upon request.

- Cost-Effective: By eliminating the need for special tools and reducing installation time, these couplings offer a cost-effective solution comparable to any compression-type airtight coupling.

Important Usage Information:

These Aluminum Reverse Threaded Barbed Couplers should NOT be installed in the following conditions:

- Wet environments or where the coupling may be submerged in water.

- Environments with strong acidic or alkaline conditions outside the pH range of 4 to 8.

- Near saltwater or where there is direct exposure to road salt runoff.

- Embedded in concrete or cement-stabilized sand.

Applications:

Ideal for innerduct systems requiring a strong, reliable, and airtight connection without the need for specialized installation equipment. Suitable for both standard and custom innerduct sizes.

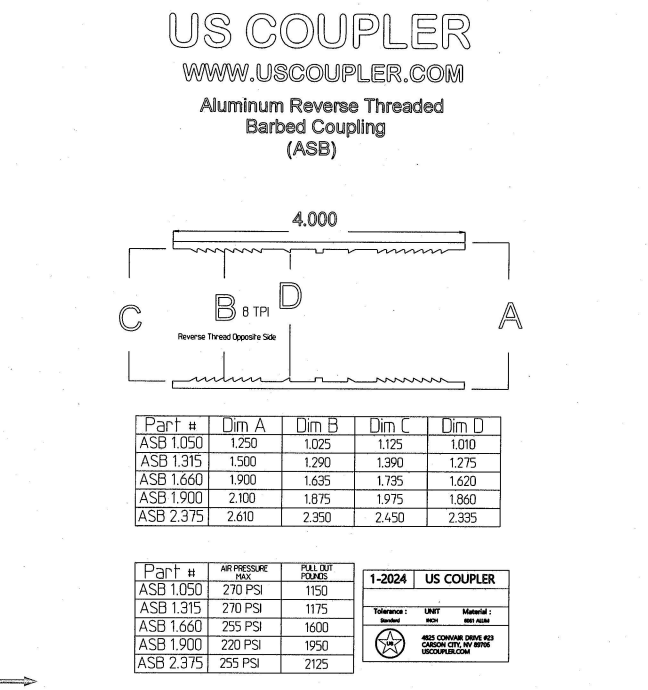

| Part # | Dim A | Dim B | Dim C | Dim D |

|---|---|---|---|---|

| ASB 1.050 | 1.250 | 1.025 | 1.125 | 1.010 |

| ASB 1.315 | 1.500 | 1.290 | 1.390 | 1.275 |

| ASB 1.660 | 1.900 | 1.635 | 1.735 | 1.620 |

| ASB 1.900 | 2.100 | 1.875 | 1.975 | 1.860 |

| ASB 2.375 | 2.610 | 2.350 | 2.450 | 2.335 |

| Part # | Air Pressure Max | Pull Out Pounds |

|---|---|---|

| ASB 1.050 | 270 PSI | 1150 |

| ASB 1.315 | 270 PSI | 1175 |

| ASB 1.660 | 255 PSI | 1600 |

| ASB 1.900 | 220 PSI | 1950 |

| ASB 2.375 | 255 PSI | 2125 |