Molded Electrofusion Branch Saddle | IPS & DIPS | 2″–12″ Outlets

Molded Electrofusion Branch Saddle | IPS & DIPS | 2″–12″ Outlets — Product Overview

Integrity Fusion Molded Electrofusion Branch Saddles provide durable, pressure-rated tapping connections for IPS and DIPS HDPE pipelines. Available in outlet sizes from 2″ through 12″, these saddles are injection-molded using high-quality PE4710/PE100 bi-modal resin for long-term strength, reliability, and performance.

Each saddle is injection-molded for exceptional dimensional accuracy and consistent fusion characteristics—superior to fabricated or machined designs. The product line includes fixed-base saddles (single pipe OD) and multi-base saddles that cover multiple pipe diameters, simplifying installation and reducing required inventory.

Key Features & Benefits

- Injection-Molded Construction — Delivers consistent melt-flow behavior and superior structural integrity versus machined or fabricated saddles.

- PE4710/PE100 Resin — High-performance bi-modal material provides increased toughness, long-term pressure capability, and reliable fusion results.

- Flexible Base Options — Offered in both fixed-base and multi-base configurations to fit a wide range of IPS and DIPS pipe diameters.

- Precision Fusion Performance — Optimized saddle geometry promotes uniform melt cooling, alignment, and high-strength fusion bonds.

- Easy Installation — Compatible with standard electrofusion control boxes for dependable, repeatable installations.

- Common Applications — Water and wastewater systems, fire protection, industrial piping, municipal systems, and general utility installations.

- Standards Compliance — PE4710/PE100 resin meets AWWA C906, ASTM F1055, FM 1613, and NSF/ANSI 61. FM 200 / FM 232 where indicated.

Pressure Ratings

IPS & DIPS Base Sizes:

FM 200 / FM 232 Approved (where indicated)

PE4710 pressure class ratings per AWWA C906 & ASTM F1055

Electrofusion Branch Saddle Dimensions & Ratings

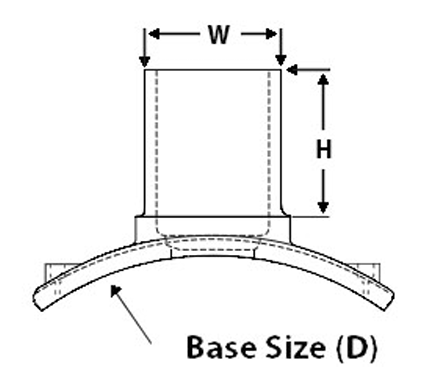

Dimensions and performance data for all fixed-base and multi-base models, including FM approvals, saddle height (H), and strap quantities.

Dedicated Base Saddles — SDR 11/17

| Outlet Size | Base Size | H (in.) | Straps | FM Class | Item Code |

|---|---|---|---|---|---|

| 2″ IPS | 2″ IPS | 3.50 | 1 | FM 150 | 200285 |

| 3″ IPS | 3.50 | 1 | FM 150 | 200279 | |

| 4″ IPS | 3.50 | 1 | FM 150 | 200276 | |

| 4″ DIPS | 3.50 | 1 | FM 150 | 200275 | |

| 3″ IPS | 4″ IPS | 4.30 | 2 | FM 150 | 200280 |

| 14″ IPS | 4.30 | 2 | FM 200 | 200207 | |

| 16″ IPS | 4.30 | 2 | FM 200 | 200208 | |

| 20″ IPS | 4.30 | 2 | FM 200 | 200219 | |

| 8″ IPS | 12″ IPS | 7.90 | 2 | FM 200 | 200225 |

| 12″ DIPS | 7.90 | 2 | FM 200 | 200226 | |

| 22″ IPS | 7.90 | 2 | FM 200 | 200211 | |

| 24″ IPS | 7.90 | 2 | FM 200 | 200282 |

Multi-Base Saddles — SDR 11/17

{{ multi-base-rows-here }}

| Outlet Size | Multi-Base Range | H (in.) | Straps | FM Class | Item Code |

|---|

Required Large Outlet Positioners — 8″ & 12″ Outlets

These outlet positioners are required when electrofusing 8″ or 12″ outlets onto 18″–48″ multi-base saddles. They ensure correct support, alignment, and load distribution during fusion.

| Outlet Size | Required For Base Sizes | Item Code |

|---|---|---|

| 8″ IPS | 18″–48″ IPS/DIPS | 200299 |

| 12″ IPS | 18″–48″ IPS/DIPS | 200298 |