Series 735 PVC x HDPE Transition Fitting | IPS

$45.90

Unit price

/

Select Option

Series 735 PVC x HDPE Transition Fitting | IPS — Product Overview

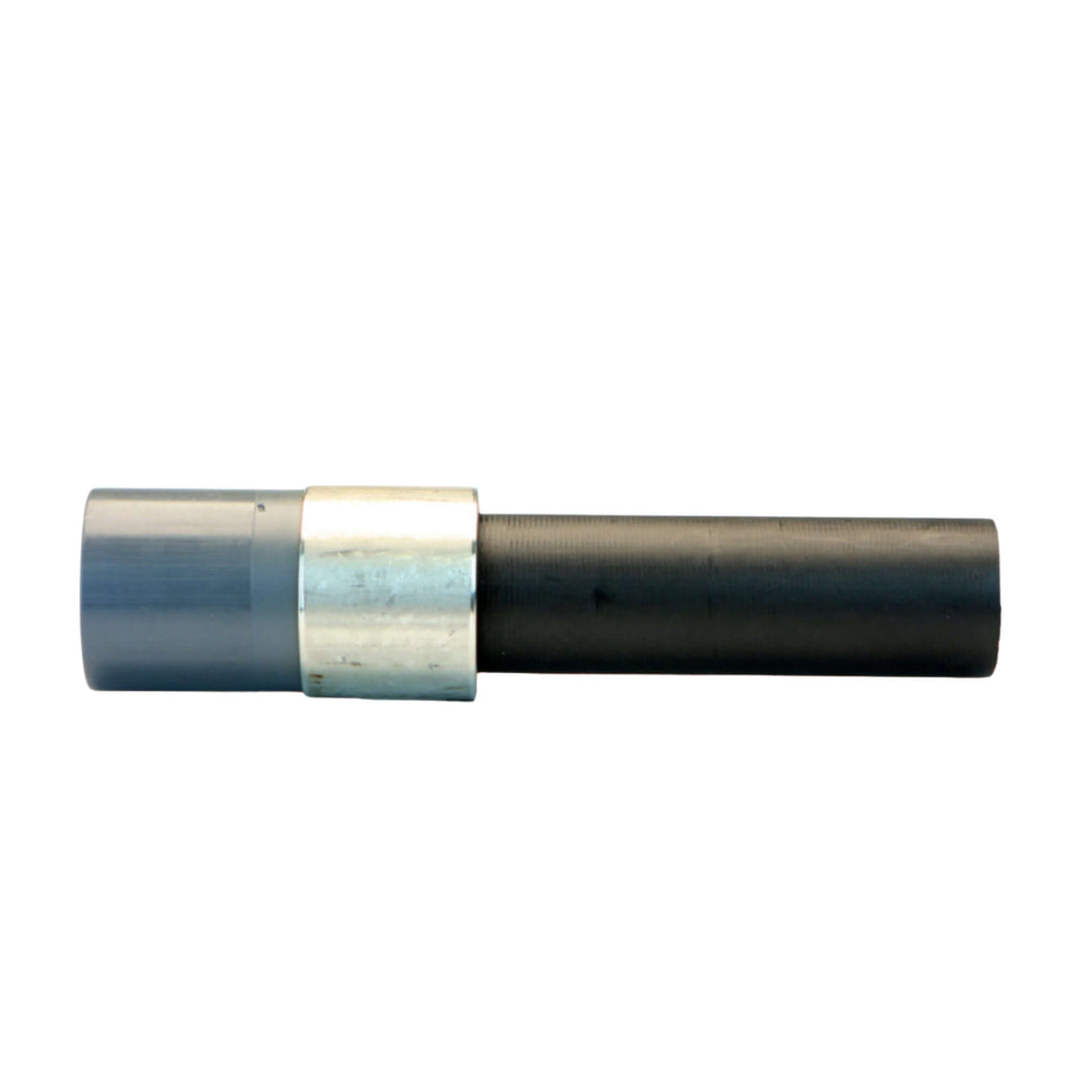

Series 735 PVC x HDPE Transition Fittings create a secure, leak-free connection between rigid PVC pipe and HDPE pipe. Each transition is hydraulically pressed to permanently seat the HDPE pipe into a machined PVC coupling with a multi-level barb system. This manufacturing method provides a durable radial-compressed joint engineered for long-term reliability in municipal, industrial, and utility applications.

Key Features & Benefits

- Hydraulic-Pressed Bond – HDPE pipe is mechanically pressed into a precision-machined PVC coupling for a permanent, leak-free seal.

- High-Quality Materials – PVC coupling meets ASTM D1784 Cell Class 12454; HDPE pipe meets ASTM F714 and ASTM D3350 (PE3408/PE4710).

- Exceptional Stress-Crack Resistance – HDPE exceeds 5,000-hour ESCR performance per ASTM D1693 (Condition C).

- Stainless Steel Locking Insert – 304 stainless steel insert manufactured to ASTM A249/A269 or SA-312 standards.

- NSF 61 Compliant – Certified for potable water applications.

Applications

- Municipal and commercial water systems

- Industrial and chemical piping transitions

- Gas distribution and pressure-rated systems

- Drain, waste, vent (DWV) conversions

Material & Technical Specifications

| Component | Specifications |

|---|---|

| PVC Coupling | Rigid PVC, ASTM D1784 Cell Class 12454; machined multi-level barb design |

| HDPE Pipe | Meets ASTM D3350 (PE3408/PE4710) and ASTM F714; density ≥0.955 g/cm³; melt index ≤0.15 g/10 min; tensile 3,200–3,500 psi; ESCR >5,000 hrs |

| Stainless Steel Insert | 304 stainless steel; meets ASTM A249/A269 or SA-312 |

| Pressure Rating | Rated to HDPE pipe pressure class with 2:1 safety factor at 73.4°F |

| Warranty | 1 year from substantial installation completion |

Order Guide

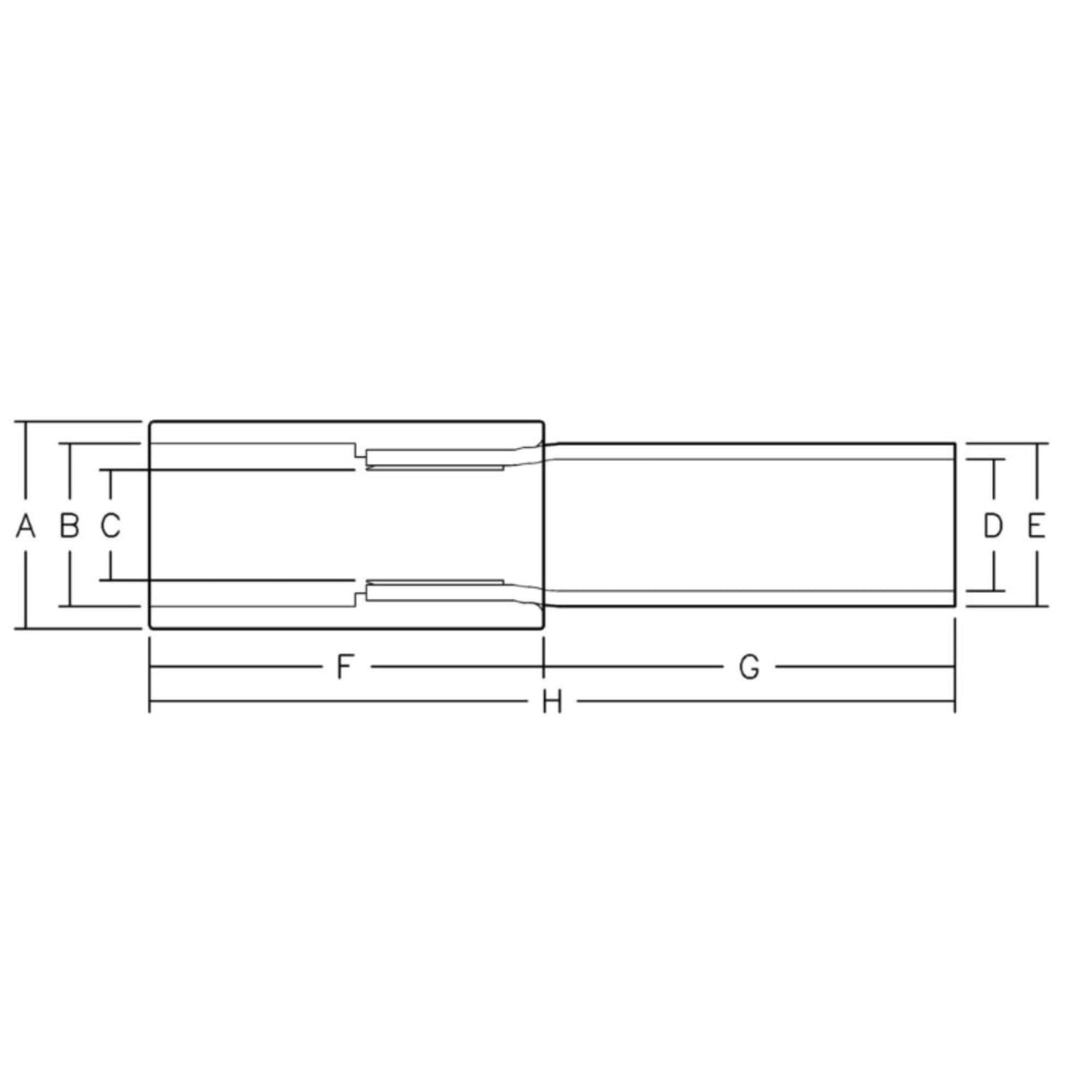

| Nominal Size (In.) | PVC O.D. (A) | PVC I.D. (B) | Est. I.D. Pressed SDR 9 (C) | Est. I.D. Pressed SDR 11 (C) | HDPE I.D. SDR 9 (D) | HDPE I.D. SDR 11 (D) | HDPE O.D. (E) | PVC Length (F) | Exposed HDPE Length (G) | Total Length (H) |

|---|---|---|---|---|---|---|---|---|---|---|

| 0.75 | 1.53 | 1.058 | 0.65 | 0.68 | 0.807 | 0.851 | 1.05 | 2.5 | ~7 | ~9.5 |

| 1 | 2 | 1.31 | 0.81 | 0.86 | 1.003 | 1.051 | 1.315 | 3 | ~6.25 | ~9.25 |

| 1.25 | 2.375 | 1.65 | 1.08 | 1.15 | 1.27 | 1.34 | 1.66 | 4.5 | ~5.75 | ~10.25 |

| 1.5 | 2.375 | 1.91 | 1.15 | 1.26 | 1.453 | 1.533 | 1.9 | 4.5 | ~5.75 | ~10.25 |

| 2 | 3.025 | 2.375 | 1.54 | 1.64 | 1.815 | 1.917 | 2.375 | 5.75 | ~5.5 | ~11.25 |

| 3 | 4.3 | 3.5 | 2.48 | 2.63 | 2.675 | 2.836 | 3.5 | 6.5 | ~4.5 | ~11 |

| 4 | 5.56 | 4.5 | 3.17 | 3.36 | 3.44 | 3.633 | 4.5 | 6.5 | ~8.5 | ~15 |

| 6 | 8 | 6.625 | 4.5 | 4.8 | 5.07 | 5.35 | 6.625 | 12 | ~18 | ~30 |

| 8 | 10 | 8.625 | 6 | 6.3 | 6.59 | 6.96 | 8.625 | 12 | ~18 | ~30 |