Fiberglass Stop Coupling - Double Bell Fitting (XW)

Fiberglass Stop Coupling - Double Bell Fitting (XW) — Product Overview

A Fiberglass Stop Coupling, commonly referred to as a double bell fitting, is an essential component in plumbing and piping systems. It is designed to connect two fiberglass pipes of the same diameter, creating a secure and seamless link between them. Often used in above-ground installations, this fitting is crucial for applications that require a robust, durable, and easily installable solution for joining fiberglass pipes.

Design and Construction

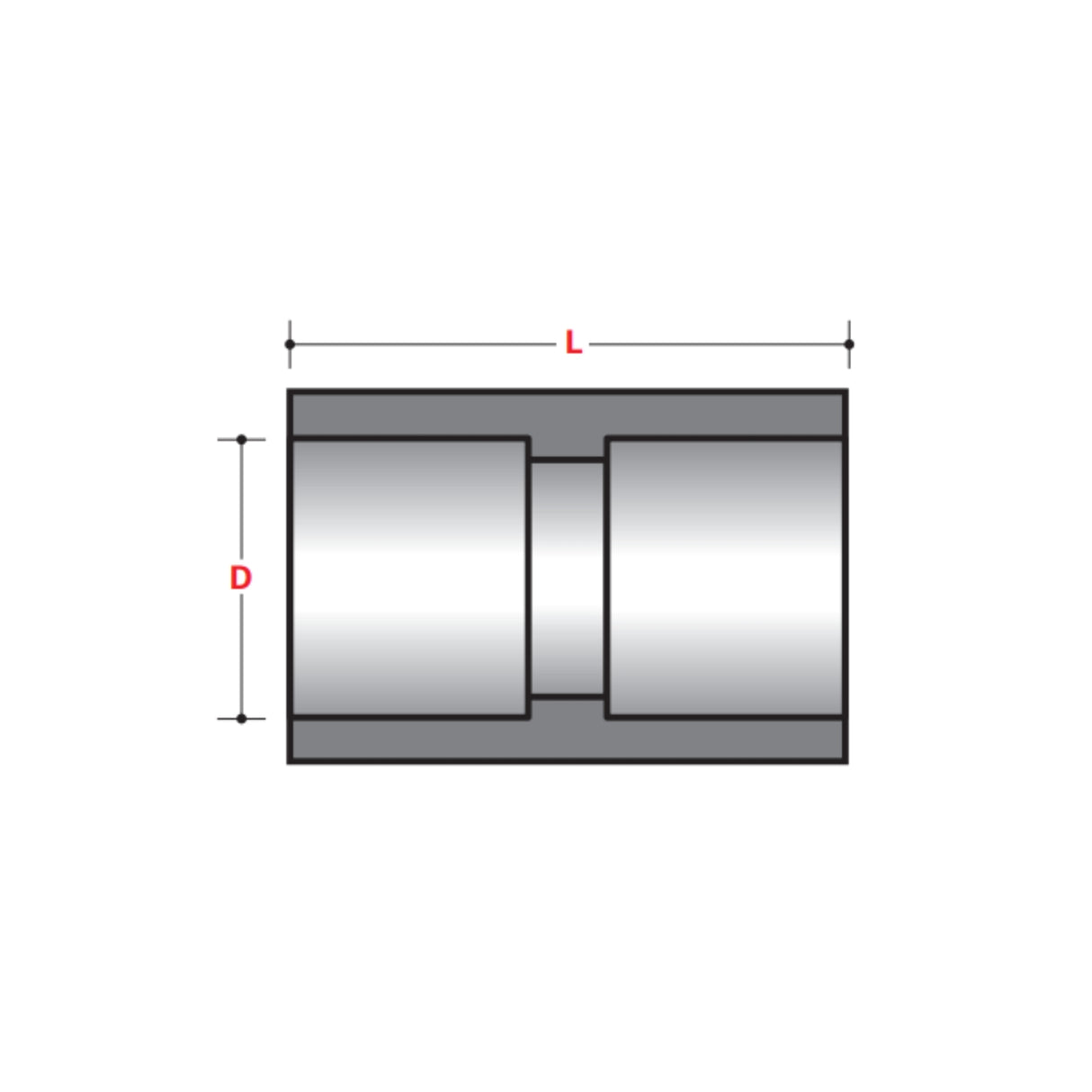

The double bell design of this fitting features two bell-shaped ends, which are engineered to receive the ends of two fiberglass pipes. These bell-shaped sections create a snug fit, allowing the pipes to slide into the fitting. The "stop" aspect of the coupling refers to a built-in shoulder or internal lip inside the fitting, which prevents the fiberglass pipes from fully sliding through. This stop feature ensures that the pipes are securely held within the fitting, reducing the risk of them slipping out or becoming disconnected under pressure.

The stop coupling typically has the following components:

- Two bell-shaped ends: These are the sections where the fiberglass pipes are inserted.

- Stop or shoulder: The internal feature that stops the pipes from moving further into the coupling. This ensures a secure connection.

- Sealant or O-ring: In some designs, rubber O-rings or sealants are used to further enhance the connection, preventing leaks and ensuring a tight fit.

Materials

Stop couplings are made from a variety of materials, each selected based on the specific needs of the piping system. Common materials include:

- Fiberglass: Corrosion-resistant and strong, fiberglass stop couplings are ideal for applications requiring lightweight, durable, and reliable connections in environments where corrosion is a concern.

- PVC (Polyvinyl Chloride): Lightweight, corrosion-resistant, and cost-effective. PVC stop couplings are widely used in plumbing and irrigation systems.

- Copper: Strong and resistant to corrosion, copper stop couplings are typically used in water supply and heating systems.

- Steel and Stainless Steel: Used in applications that require high strength and resistance to extreme temperatures or pressures.

- Cast Iron: Common in larger diameter piping systems or where extra strength is required.

Applications in Above-Ground Systems

Fiberglass stop couplings are commonly used in above-ground piping systems. These installations might involve a range of piping systems such as:

- Water Supply Systems: Connecting sections of fiberglass water pipes in residential, commercial, or industrial buildings.

- Sewer and Drainage Systems: Ensuring that pipes in above-ground sewer systems are properly connected and sealed.

- Irrigation Systems: Connecting sections of fiberglass irrigation pipes to distribute water across agricultural or landscaped areas.

- Fire Protection Systems: Joining fire sprinkler lines or hydrant systems to ensure water can be properly distributed in the event of a fire.

Key Benefits:

- Ease of Installation: One of the primary benefits of stop couplings is their ease of installation. Fiberglass pipes can be inserted into the bell ends, and the fitting is typically secure without requiring extensive tools, making them ideal for both professional plumbers and DIY installations.

- Versatility: Stop couplings can be used with various types of fiberglass pipes, making them versatile. Whether dealing with PVC, steel, copper, or fiberglass, these couplings accommodate different pipe types depending on the system's needs.

- Durability and Strength: Double bell couplings are designed to withstand a range of pressures and conditions. Whether used for fiberglass water supply or industrial applications, these couplings offer long-lasting performance when installed correctly.

- Cost-Effective: Especially in large piping systems, the cost of materials and installation is crucial. Stop couplings provide a cost-effective way to connect fiberglass pipes compared to other fitting types that may require threading, welding, or other complex methods of attachment.

- Leak Prevention: The secure fit and the optional use of sealants or O-rings in the stop coupling provide superior leak resistance, which is vital for maintaining the integrity of the piping system.

Applications and Industry Usage

- Residential and Commercial Plumbing: In above-ground fiberglass water supply and drainage systems, stop couplings offer a simple way to join fiberglass pipes. They are also commonly used for repairing or extending piping systems.

- Irrigation Systems: For agricultural purposes, stop couplings are vital in creating flexible fiberglass irrigation systems that can be extended or reconfigured easily.

- Industrial Systems: In industrial environments where above-ground fiberglass piping is used for transporting fluids, gases, or other substances, stop couplings ensure that systems remain intact and leak-free under varying conditions.

- HVAC Systems: In heating, ventilation, and air conditioning systems, these couplings help in connecting various sections of the fiberglass pipework, ensuring efficient airflow and temperature regulation.

Limitations and Considerations

While stop couplings are versatile, they may not be ideal for every application. Some limitations include:

- Limited Flexibility: Once the fiberglass pipes are inserted and sealed into a stop coupling, they cannot easily be adjusted or repositioned.

- Temperature and Pressure: The material chosen for the coupling should match the requirements of the system. For example, PVC couplings might not withstand extreme temperatures or high-pressure applications as well as fiberglass or metal couplings.

By choosing fiberglass stop couplings for your next installation, you can ensure reliable and durable connections for your above-ground fiberglass piping systems.

| Nominal Size | Type | Above Ground Item No | D (Diameter) | L (Length) | Weight (LBS) | Weight (KG) |

|---|---|---|---|---|---|---|

| 3/4" | XW | 07C-XW-40 | 1.435" (36) | 6" (152) | 0.22 | 0.10 |

| 1" | XW | 10C-XW-40 | 1.700" (43) | 6" (152) | 0.29 | 0.13 |

| 1-1/4" | XW | 12C-XW-40 | 2.045" (52) | 6" (152) | 0.36 | 0.16 |

| 1-1/2" | XW | 15C-XW-40 | 2.285" (58) | 6" (152) | 0.39 | 0.18 |

| 2" | XW | 20D-XW-40 | 2.525" (64) | 6" (152) | 0.88 | 0.40 |

| 2-1/2" | XW | 25D-XW-40 | 3.025" (77) | 6" (152) | 1.08 | 0.49 |

| 3" | XW | 30D-XW-40 | 3.525" (90) | 6" (152) | 1.25 | 0.57 |

| 3-1/2" | XW | 35D-XW-40 | 4.025" (102) | 6" (152) | 1.87 | 0.85 |

| 4" | XW | 40D-XW-40 | 4.525" (115) | 6" (152) | 2.00 | 0.91 |

| 5" | XW | 50D-XW-40 | 5.525" (140) | 6" (152) | 2.50 | 1.13 |

| 6" | XW | 60D-XW-40 | 6.525" (166) | 6" (152) | 2.90 | 1.32 |

| 8" | XW | 80C-XW-40 | 8.925" (227) | 10" (254) | 3.00 | 1.36 |